Operational Efficiencies: Outsourcing storage can improve efficiency by allowing organizations to focus on their core activities, such as research, development, and production, while leaving the management of biological collections to experts in the field.

Space and Resource Optimization: Offsite storage allows laboratories to free up valuable space for critical activities. It eliminates the need for organizations to invest in CapX and maintain costly storage infrastructures.

Risk Mitigation: Offsite storage providers like Precision have robust disaster recovery plans and redundancies. This helps mitigate risks associated with unexpected events, such as power outages, equipment failures, or natural disasters.

Read on to learn about ultra-low temperature storage solutions and the benefits of storing and preserving samples offsite.

What is an Ultra Cold Freezer Storage Service?

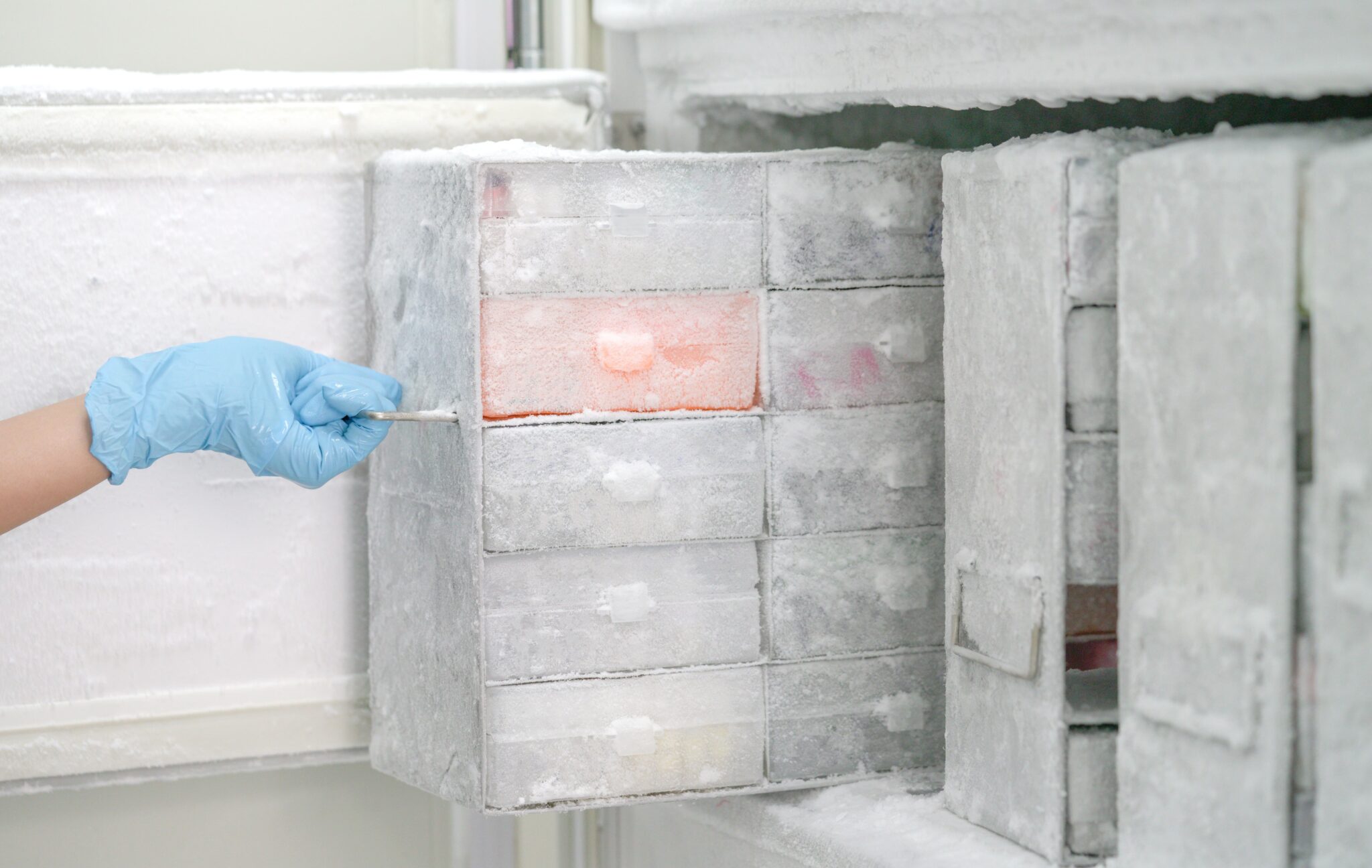

Precision Storage offers a perfect solution for preserving most types of biological materials at -80°C over extended periods of time. With locations from coast to coast, we offer comprehensive, cost-effective biorepository services. Our employees are the best trained in the industry and are critical to all of our contract off-site cGMP biostorage and ISO-compliant offerings.

Ultra-low freezers safeguard temperature-sensitive biological samples and other materials, such as:

PRECISION’S OFFSITE ULT STORAGE SOLUTION

Our ULT storage solution includes:

- High-quality units with a leading ENERGY STAR rating.

- Remote temperature monitoring systems.

- Compliance with regulatory standards (cGMP, ISO, and FDA)

- Highly customizable solutions to meet specific needs.

- 24/7/365 security with controlled access and alarm response.

- Precision can store material within customer-owned units or in our freezers.

Get a quote from Precision today!